The Premier Place for Cannabis Beauty and Business News

Education

How is CBD oil made?

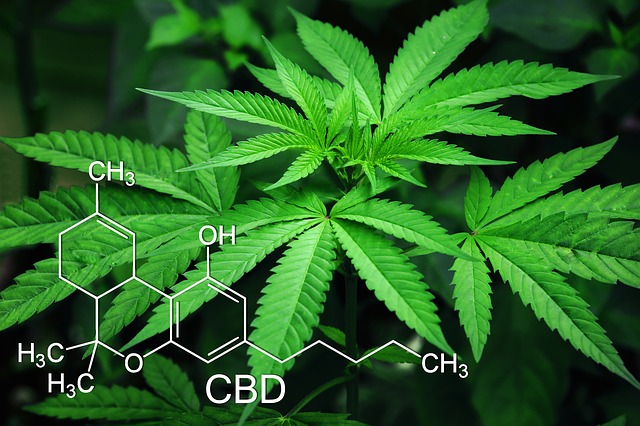

Cannabidiol (CBD) can be briefly defined as a natural extract from the hemp plant. It contains no trace of THC so is both legal and non-intoxicating. Unlike THC, CBD has no addictive or psychoactive elements. As a result, many people are known to use CBD for its restorative properties.

CBD is available mostly in oil form, which is extracted from the hemp plant and then mixed with a ‘carrier’ oil. In this article we will explain how the Grass & Co. CBD Oil is made, outlining the range of processes involved in cultivating, extracting, and refining CBD oil.

CULTIVATING THE HEMP PLANT

First, the CBD must be extracted from ‘industrial hemp’ that is grown legally in Europe and the US. This is cultivated from seeds that contain less than 0.2% THC as per EU regulations. Instead of THC, these plants are grown and nurtured so that they contain high levels of CBD.

EXTRACTING, REFINING AND DISTILLING CBD OIL FROM THE HEMP PLANT

There are many different techniques for extracting CBD from the hemp plant.

Generally speaking, any commercial CBD extraction technique will require the use of solvents. These solvents are important because they’re highly efficient in separating the CBD molecule from the other compounds found in the cannabis plant, and in purifying the solution. Afterwards, the solvent evaporates, leaving behind only pure CBD Oil.

CO2 EXTRACTION

The most common method for extracting CBD is ‘CO2 extraction,’(supercritical carbon dioxide). This method uses a closed-loop extractor, a system for extracting essential oils for perfumes, as well as creating food additives. The hemp is placed in a chamber which is then filled with carbon dioxide. By applying pressure to the chamber, the carbon dioxide is turned to liquid, which then absorbs the hemp’s oils and flavours. The end result is a liquid consisting of both carbon dioxide and CBD. This liquid is then pumped into a final chamber where the carbon dioxide is turned into gas.

Although this extraction process is known to be safe, efficient and with an end result that is potent, it’s important to be aware that this process isn’t always alcohol free. Material extracted with CO2 typically needs to be further refined with an alcohol solvent to create CBD isolate or distillate.

ALCOHOL EXTRACTION

Another viable way of extracting CBD is by using liquid solvents such as ethanol, butane, or isopropyl alcohol. This is widely regarded as one of the simplest extraction methods. As a plant-based solvent, experts claim that ethanol helps to maintain the hemp’s natural chemical properties during extraction. However, some tests have shown that the solvent residue isn’t always fully eliminated during the evaporation step. In addition, when natural solvents like ethanol are used, the chlorophyll may also be extracted during the process and this gives the resulting oil an unpleasant taste.

THE GRASS & CO. EXTRACTION METHOD

As Grass & Co. are committed to delivering the best quality CBD Oil to our customers, we have discovered that alcohol (IPA) is the most effective solvent to use to ensure complete consistency during the extraction process.

The benefits of using IPA when creating clean and compliant CBD products are numerous. IPA consistently delivers high quality, pure CBD within the highest production standards. It offers an excellent safety profile and multiple medical uses, as well as being used in many health and beauty products. This extraction method plays a key role in determining the type and relative quantities of the extractable plant components that need to be removed during the purification process.

Our products also benefit from extraction machines unique to our production facility, which again ensures the highest quality standards. As a result, we are able to have more control over the purity and grade of our CBD Oil.

PURER CBD

Creating CBD isolate or distillate is not a solvent-free process, and though solvent selection is significant, it’s not the only piece that supports the extraction process. Following extraction, the CBD Oil goes through a precise, multi-stage refinement and distillation process until all that is left is the pure CBD Oil.

Grass and Co.’s range of CBD products are made using narrow spectrum CBD distillate and isolate, rather than full spectrum CBD. This ensures that each product has the correct amount of the highest quality CBD, whereas full spectrum CBD can often contain trace levels of THC. Narrow spectrum CBD isolate and distillate offer an improved taste and flavour, helping our customers incorporate CBD into their daily rituals.

TESTING

Although it’s easy to solely focus on the specific type of process or solvent a product uses, this doesn’t tell the whole story about your CBD. Extraction is only the beginning. While solvents are used in the extraction process, all that’s left in the end is refined CBD. More importantly, the quality of our final product is dependent on our stringent manufacturing practices and standards, as well as the significant investment in testing.

At Grass & Co, we rigorously lab test all our products twice. Our laboratory is one of the only which offers an accredited method of testing. We are proud to be transparent about the full process and the results. We share the full data sheet on our website on the product pages of all of our CBD products.

Source: Grass & Co.

SECTIONS

Search

Events + GALLERY

The Premiere Place for Cannabis Beauty and Business News

sections & Articles

The Premiere Place for Cannabis Beauty and Business News

Recent Articles

SEARCH RECENT TOPICS

RECENT ARTICLES

The Premiere Place for Cannabis Beauty and Business News

Cannabisness Of Beauty

is published by Cheryl Green

owner of Green Creative Group, LLC

M/WBE certified